Casting Craftmanship

Based in Takaoka City in Toyama Prefecture, NOUSAKU Corp. applies traditional Japanese casting techniques to contemporary designs to promote a unique, stylish lifestyle, representing the leading edge of a centuries-old tradition.

By NIHON ICHIBANA Century-old Family Business

http://nihon-ichiban.com/2013/07/25/nousaku-traditional-cast-techniques-applied-to-contemporary-designs/

The Takaoka area has been famous for casting for roughly 400 years, traditionally making Buddhist altar fittings made of tin and brass. NOUSAKU Corp. was established in 1916, and is managed by the fourth generation of the Nousaku family. The kanji 能 (nou) and 作 (saku) literally mean intelligent creation, and there is no better to describe the company's products.

4-Step Process

http://nihon-ichiban.com/2013/07/25/nousaku-traditional-cast-techniques-applied-to-contemporary-designs/

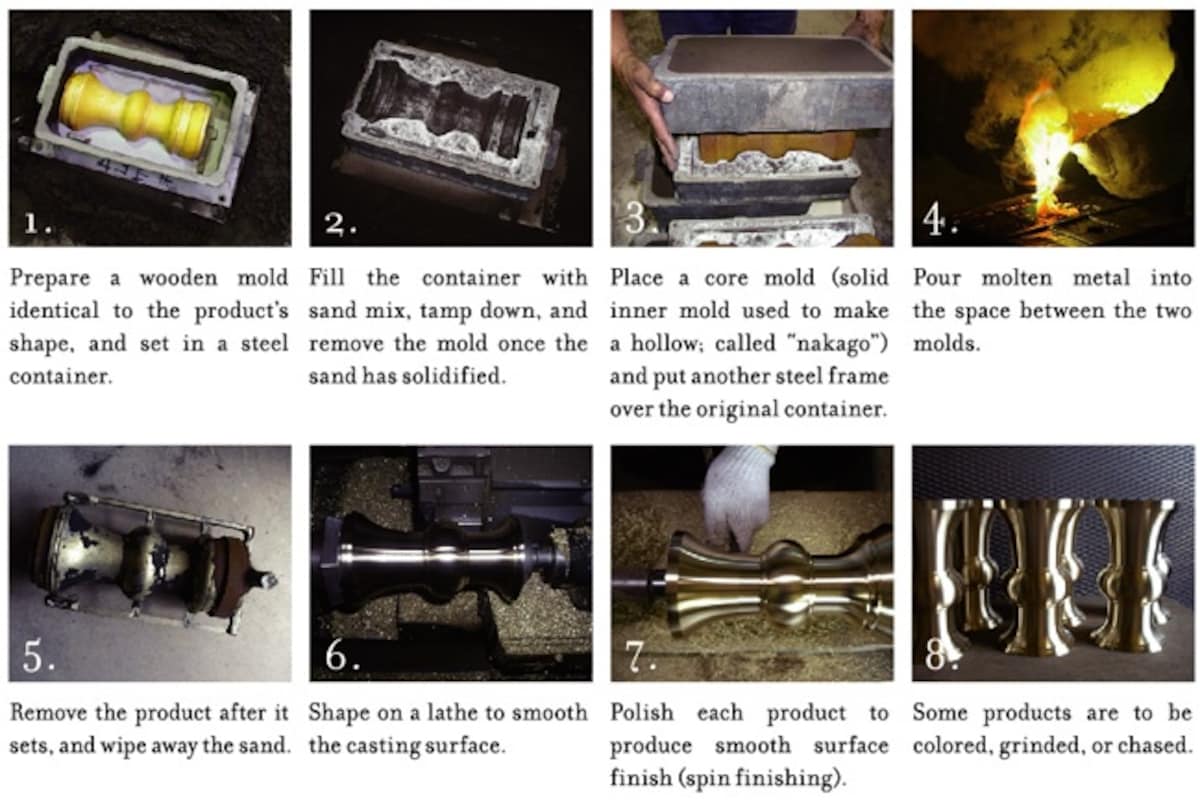

The production of NOUSAKU products requires four basic steps: mold-forming, casting, finishing and coating.

Independent craftsmen who work for multiple clients make the wooden molds, which are then stored for years. The NOUSAKU warehouse is full of hundreds of these molds that sometimes are used once every few years to renew certain parts of a temple.

Of Molds & Metal

http://nihon-ichiban.com/2013/07/25/nousaku-traditional-cast-techniques-applied-to-contemporary-designs/

During the casting process the wooden molds are placed in a steel box that is filled with a special mix of so-called "green sand." Once the sand solidifies, the wooden mold is removed, leaving the shape of the object to be produced, which is then filled with molten metal.

In one day, workers in the casting area will prepare hundreds of core molds. The next day they will all be filled with metal, and after cooling the newly created objects will be removed from the molds and the sand recycled.

The physically demanding casting area requires a lot of teamwork, but the next production step is performed by highly specialized craftsmen who work alone at their stations.

A Specialized Craft

http://nihon-ichiban.com/2013/07/25/nousaku-traditional-cast-techniques-applied-to-contemporary-designs/

Each workstation in the finishing area is used for a specific task to be performed with each product. The work in the finishing area ranges from simple polishing to the engraving of complex patterns into the objects. Craftsmen who are with NOUSAKU for many years master multiple workstations, whereas young craftsmen first struggle to reach perfection on a very small number of tasks.

External Partners

http://nihon-ichiban.com/2013/07/25/nousaku-traditional-cast-techniques-applied-to-contemporary-designs/

The last step of production is coating, which is performed by specialized external companies, with different companies used for different kind of coatings. By working together with multiple external partners for creating molds and coating, NOUSAKU helps maintain the ecosystem of the traditional craft of Takaoka casting.

Don't Knock Tin

http://nihon-ichiban.com/2013/07/25/nousaku-traditional-cast-techniques-applied-to-contemporary-designs/

In addition to brass, which is used for making many products such as wind chimes, NOUSAKU developed a new range of products made of pure tin. Known as the most expensive metal after gold and silver, tin is very malleable and flexible. Though having nearly the whiteness of silver, it does not rust easily nor will air tarnish it readily. It's significantly antibacterial, and is also known as a material with low allergic reactivity and high heat conductivity.

The history of tin dates back to around 1500 B.C., when the ancient Egyptian pharaohs were believed to have used tin tools. The Shosoin repository in Nara also contains treasures made of tin. It has been believed that water in a tin container does not spoil, and tin removes excessive bitterness from sake and produces a better flavor. Because it's known to absorb impurities and purify water, products made of tin are said to be ideal for enjoying liquor, meals, sweets or even flowers. Cooling a tin plate in a refrigerator for two to three minutes will keep the plate fresh and cold.

While it's common to add other metallic materials to provide durability and facilitate cutting work, but NOUSAKU uses tin without such additives, relying on the accumulated experience of its skilled craftsmen to overcome any potential drawbacks. Though it depends on the shape and thickness, pure tin is soft and flexible, and can be bent by hand (a crackling sound called the "tin cry" will be heard as it's bent). NOUSAKU's Flexible Ware line allows people use use these product in many creative ways.

A New Direction

https://www.youtube.com/watch?v=q8jwuXYFQ4c

The story of NOUSAKU is not only that of a craft, but also about the transformation of a business. Through most of its history, NOUSAKU was a casting firm working for other companies that would make the finished products, meaning NOUSAKU almost never saw its end customer.

It was when the fourth generation of the Nousaku family took over leadership that interest in the consumer grew. The company started working with designers to create new and interesting interior products, which received great recognition around the world. Ten years since the beginning of this transformation, NOUSAKU is on its way to becoming an interior decoration and tableware luxury brand known around the world.

An Average Age Around 30

NOUSAKU has been hiring more and more staff in recent years to cope with its increasing success. With the average employee age now around 30, an inspiring and dynamic atmosphere has grown throughout the entire company. This culture of growth and creativity informs NOUSAKU's confidence in its future, where the company is looking forward to many more fantastic new products to come.