Sleep in Comfort in Beds made with Japanese Craftsmanship

Nihon Bed has a long commitment to crafting quality beds, and its mattresses and frames can be found at the most luxurious accommodations throughout Japan.

By AAJ Editorial Team

The Nihon Bed logo has become a mark of high-quality mattresses that offer the most comfortable sleeping experience through traditional Japanese craftsmanship.

Founded in 1926, Nihon Bed will soon celebrate its centennial. In the post-war period, the company headquarters (above) led a renewed effort to supply the country with quality beds, including the Occupation forces.

Nihon Bed is Japan’s oldest bed maker, the brainchild of a young man who began his career as a page boy at Tokyo’s famed Imperial Hotel. Takeharu Usami had joined the hotel’s staff at the end of the Meiji period (1868—1912), at a time when almost everyone in the country was sleeping in the traditional style—on futon laid out on tatami mats. Takeharu Usami spent 10 years at the hotel before joining a trading company and traveling to England, where he became deeply interested in bringing “bed culture” to his home country.

After researching beds and mattresses that he felt would be suitable for the Japanese market, he founded Nihon Hane Kogyo (Nihon Bed’s original name) in 1926. For the next 90-plus years, the company has been making beds for the hotel service industry and home use as the Japanese style of living changed over the years. Nihon Bed has always been quick to respond to changes in sleeping habits, developing new products that reflect the comfort and quality for which the company has become known. “Coming from a culture of sleeping on futon, Japanese once preferred a harder bed,” says Hiroshi Abe, Manager of the Product Planning Department. “But in more recent years, people began looking for softer mattresses, closer to the European style.”

Today, Nihon Bed’s products can be found in homes of discerning customers and Japan’s most luxurious hotels, including the Imperial, the Okura and at many of the Hoshino Resorts. VIPS from all over the world, in fact, sleep on the beds at State Guest Houses both in Tokyo and Kyoto. Many of these beds are made to specific requests by the hotel. But the high-quality standards of such customers is also available in beds made for use at home. To meet the needs of a wide variety of clientele who may prefer different levels of support—from hard to soft—Nihon Bed offers a broad range of mattresses and frames.

The Height of Bed Technology: The Silky Pocket Mattress

The Silky Pocket Mattress series feature a unique design of 1200 individual springs that move independently of each other to offer total body support. The thickness of the spring’s coils are different depending on the choice of mattress.

Some four decades ago, Nihon Bed used their home-grown technology to develop the world’s first heat treated springs, which are fitted in individual non-woven fabric pockets. The heat treatment works to stabilize and maintain the springs‘ shape. This led to further development, until the “Silky Pocket Mattress” series was launched in 1996. Inside each of these mattresses are a total of 1200 heat-treated, rust-proof springs, all of the same size and strength.

Nihon Bed’s Silky Pocket series of mattresses are available in hard, regular and soft types. The difference is created by the thickness of the wire used in the coil, as well as the use of a variety of fillings, such as urethane and felt. “When choosing a mattress,” says Mr. Abe, “I suggest lying down, relaxing, and staying for at least several minutes to get a true feel for the support.”

Nihon Bed frames are modern, stylish and somewhat minimalist, reflecting a classic Japanese aesthetic. They tend to be low to the ground, giving an airy feel to even a small room. The company also regularly works with well-known designers in developing new looks.

Hiroshi Abe, manager of the Product Planning Department, gives advice on selecting the appropriate mattress.

Nihon Bed’s History of Monozukuri Craftsmanship

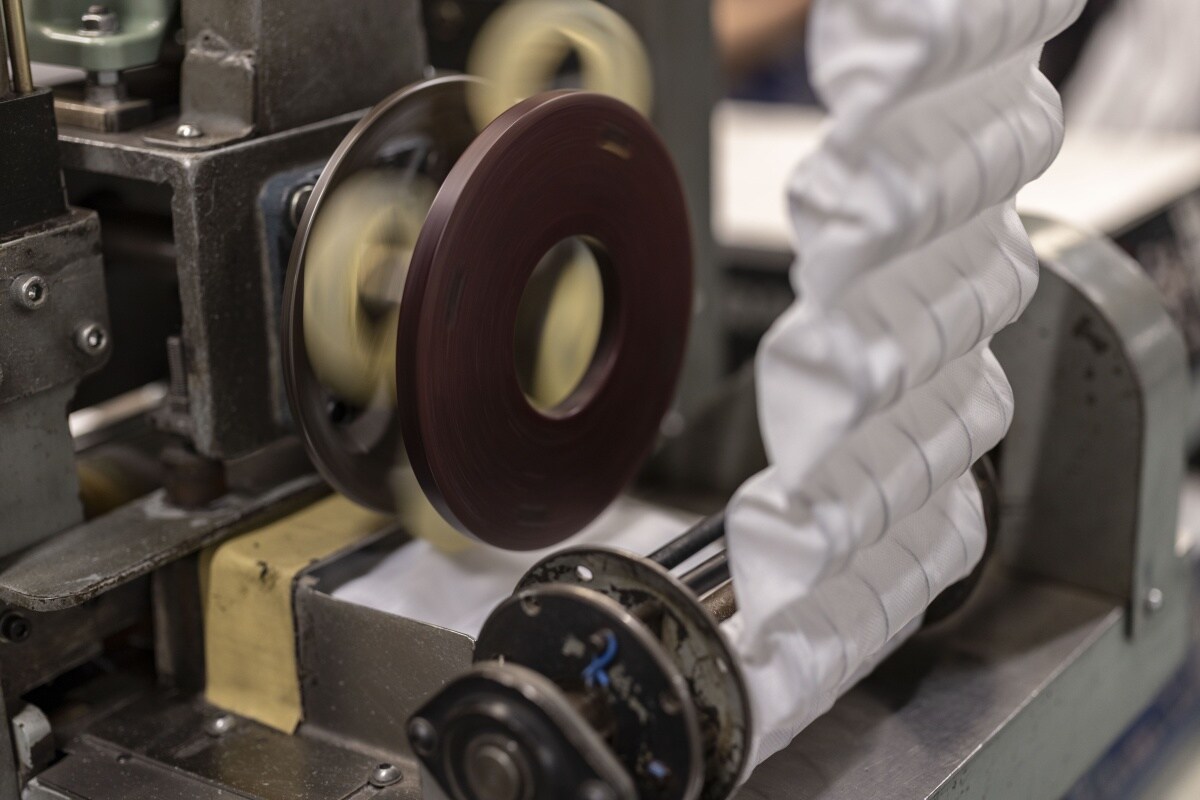

Hands-on craftsmanship and machines of Nihon Bed’s own design are found everywhere at the Nihon Bed factory in Ibaraki Prefecture. Here, the top layer of a mattress is cut and stitched by machine under the watchful eye of an experienced employee.

The second floor of Nihon Bed’s factory in the countryside of Ibaraki Prefecture north of Tokyo is open and spacious, with men and women employees moving efficiently among the many machines making the various parts of the mattress surfaces. Making mattresses is a labor-intensive business, and the process at Nihon Bed is very much hands-on, a testament to traditional Japanese craftsmanship. “The most precise machines are human beings,” says Takao Kuramochi, the factory manager. This is the attitude born of Japan’s long tradition of monozukuri, a mindset that strives for perfection.

Each step is a collaboration between the workers and the machines, many of which have been developed from scratch by Nihon Bed employees to serve a very particular purpose. A Nihon Bed-designed stamping machine for the vent eyelets, for example, was designed by Nihon Bed to make sure their insertion would not weaken the fabric. “They are not just for ventilation,” says Mr. Kuramochi, “The vents are needed to give the air inside the mattress somewhere to go when someone sits or lies on the bed, which contributes to the softness of the mattress.” Many mattress makers today have abandoned the use of these vents, but Nihon Bed continues to insert them in all their mattresses.

The factory floor is where everything comes together to form the final mattresses, from creating the coils to the final sewing of the edges, and the tufting that goes into the top-of-the-line mattresses.

Once again, a collaboration between craftsman and machine. Here, one of the final, most difficult steps in the production of a top-of-the-line Silky Couture mattress: stitching the edges of the mattress surface to the side panels.

Two workmen operate the stamping machine that glues the urethane mattress surface to the coiled springs.

Attention to Detail and an Eye toward New Ideas

One machine coils the wire into springs, then heats them at a high temperature before cooling and inserting them into the non-woven fabric pockets. The machine was developed by Nihon Bed to bring new technology to its traditional craftsmanship.

Another machine of Nihon Bed-design is very much a multi-tasker. It not only coils the hybrid carbon wire but heats the springs to a temperature of 300℃ before but running them through a cooling bath. Then, under the watchful eyes of a factory worker, the machine smoothly inserts the coils into the non-woven fabric pockets that comprise the current flagship product, the Silky Pocket mattresses.

The mattresses take shape at each step on the way across the factory floor. At one section, the fabric pockets are glued together to form a mattress-size shape. Not far away, two factory workers glue the urethane and wool surface pads to the top of the 1200 cloth springs. In the far corner, two craftsmen are taking the final step in making a high-end Silky Couture mattress. Using special hand tools, they punch strands of fabric through the mattress by hand before fixing both ends with wool tufts imported from France. This keeps the coils from shifting during use.

A workman (above) punches one of any fabric ribbons through a Silky Couture mattress, before fixing each end with a wool tuft (below) that has been imported from France.

Nihon Bed has continued to introduce other features that can enhance the sleeping (and interior living) experience. While the mattresses are available in soft, regular, and hard versions for sleeping comfort, a mattress feature that feels soft against the back of the knees when sitting on the mattress has also been developed. This has resulted in a mattress that can be used as a king-size bed unit by combining single-size beds as requested by hoteliers, while still providing the same overall body support, and allowing for a good night's sleep even when in the middle position of a king-size bed unit.

“We invest in quality production and new developments,” says Mr. Kuramochi, “instead of spending on advertising. We think it’s why we are able to make products that other companies can’t easily imitate." Nihon Bed is not resting on its laurels. “We’ll soon be celebrating 100 years as a bed maker,” Kuramochi says. “Our next challenge is to come up with an innovation that will even surpass the comfort and quality of our Silky Pocket mattresses.”

Factory manager Takao Kuramochi holds one of the coils that feature in the company’s highly regarded Silky Pocket mattresses. Notice the larger dimensions in the center, which allows for support to vary depending on the weight applied.

Official Page

nihonbed.com/english/

Instagram

Nihonbed global official